Fast and cost efficient CFD optimization of a Dallara Formula 3 car by means of adjoint and RBF mesh morphing

Simulation had a major impact in Our life, changing the way we think and design new products. From aerospace, to civil and biomedical, to name a few, all the fields of engineering have been interested by this ongoing revolution. We can safely say that the engineer of the 21ST century can inspect, study, design and improve like never before.

In this scenario, the technological evolution and the increase of computational power had an irreplaceable role. Navier Stokes equations have been known for two centuries - French engineer Claude-Louis Navier started this incredible journey exactly two hundreds years ago, in 1821 - but it is only in the last decades that we managed to use them to their full potential.

Today complex and refined CFD simulations, requiring days just few years ago, can be completed in a matter of hours.

This leap forward in terms of computational power comes however at a cost. The increasing sensibility toward environmental sustainability and the awareness of the ecological problem are today pushing in the direction of a new scenario, in which a new balance between computational resources and environmental attention must be found. In motorsports, this shift in the approach was made evident by the computational restrictions introduced by FIA rules, limiting de facto the ability of teams in using traditional and computationally intensive approaches to optimization, and encouraging toward the adoption of more subtle and technologically advanced numerical methods other than the use of brute force.

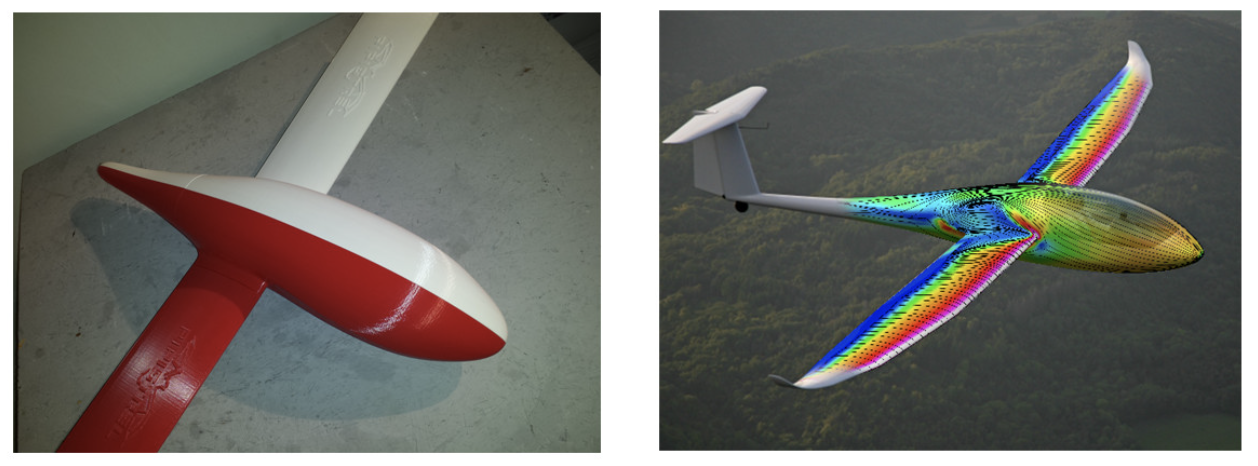

At the University of Rome “Tor Vergata”, in joint cooperation with Dallara Automobili, we accepted the challenge and, together with our partner RBF Morph, we have developed a promising and efficient approach. As demonstrated by the study we will present at Simulation World 2021, “Fast and cost efficient CFD optimization of a Dallara Formula 3 car by means of adjoint and RBF mesh morphing”, the synergy between adjoint methods and mesh morphing can deliver a turnkey solution able to accelerate optimisation reducing time and costs. By one side the adjoint solver can provide for a given shape, at the cost of a single added evaluation, the sensitivity of a given objective function - such as drag force, pressure drop or downforce - with respect to its variation. By the other, morphing methods based on Radial Basis Functions - such as the one provided by RBF Morph with its Fluent add-on - can efficiently compute shape variations even for meshes composed by millions or billions of cells.

We will show you how a new clever tool, called (rbf-adjoint-interactive), can create a new optimization paradigm in which the engineer can inspect - also at a post processing stage - the influence of any given shape parameter in real time without the need of a new CFD simulation, and we will demonstrate it on a Dallara Formula 3 car, reducing its aerodynamic drag in order to gain 0.43 drag points.

Are you interested on how you can inspect, study, design and improve with no added CFD simulation?

Stay with us at ANSYS Simulation World 2021!